Ute Zahn, Violin Maker

This is my third iteration of Giuseppe Guarneri del Gesu's "Lord Wilton" violin, fresh from the tanning booth and ready for its ground coat. While it looks quite dark now, each subsequent layer of ground, sealer and varnish will miraculously lighten the appearance of the tan. Just one of the many mysteries that keep my job fresh and interesting!

0 Comments

Prodigal's ramblings Having just returned home after two back-to-back trips, I'm very much looking forward to spending some solid chunks of time in my workshop building things again.

It was lovely to go to California and meet everyone at the Metzler Violin shop in Glendale, in the LA area. The shop is charming and set up to serve a broad cross section of the music community, and the exhibit of contemporary American makers the Metzlers were hosting was well-organized, well-publicized and, as far as I could tell, well-attended. With amazing tirelessness, the Metzlers will also take the show on the road, traveling to Las Vegas with about 100 instruments in tow -- hats off to them! For some highlights of individual instruments being introduced, click http://www.violinist.com/blog/laurie/20174/21113/ After a quick turnaround over the Easter weekend, I packed my bags again to travel once more to Port-of-Spain, Trinidad. This was part of Luthiers sans Frontieres' ongoing engagement with the University of Trinidad and Tobago's music department, specifically focusing on training young musicians the art and craft of violin repairs and set-up and bow rehairs and repairs. I worked with two of our long-term students, Akil Patrick and Ayana Smith. I'm very excited we succeeded in setting them up with two internships in US violin shops for this summer, and are hoping they'll be able to attend a varnish workshop while they're stateside, too ... here's keeping my fingers crossed their visas will come through! Meanwhile, I'll keep them on their toes via Skype lessons. It's quite telling that, as a token of the students' appreciation, I was handed a magnifying glass .... We did manage to squeeze in some extracurricular activities (a yoga class, a morning at the beach, a dance performance, and some socializing with the generous, caring, and gifted UTT music teachers who, over the years, have become our friends). All in all, a lovely time which has inspired me to now throw myself into my own work! I'll soon be riding the rails all the way out to Los Angeles, California, where the Metzler Violin Shop will host an exhibition showcasing the work of contemporary American luthiers. I am very pleased a couple of my instruments will be included in the show. A link to the event can be found here.

Having to speed-varnish a viola and a cello is a big task .... especially the cello, most especially because the result of my last varnish experiment is rather like tar. Which is to say, it contains a lot of colour, obliterating the need for added pigment; and also, that it is thick, stringy, sticky beyond belief. Warmed up and padded out on a nicely-figured piece of maple, it does look rather attractive, though ....

No longer in the works: Some instruments put up a real fight against being born .... but finally, here is my iteration of Obie-1, the instrument designed by committee in Oberlin under the capable leadership/draftsmanship of Australian luthier Hugh Withycombe.

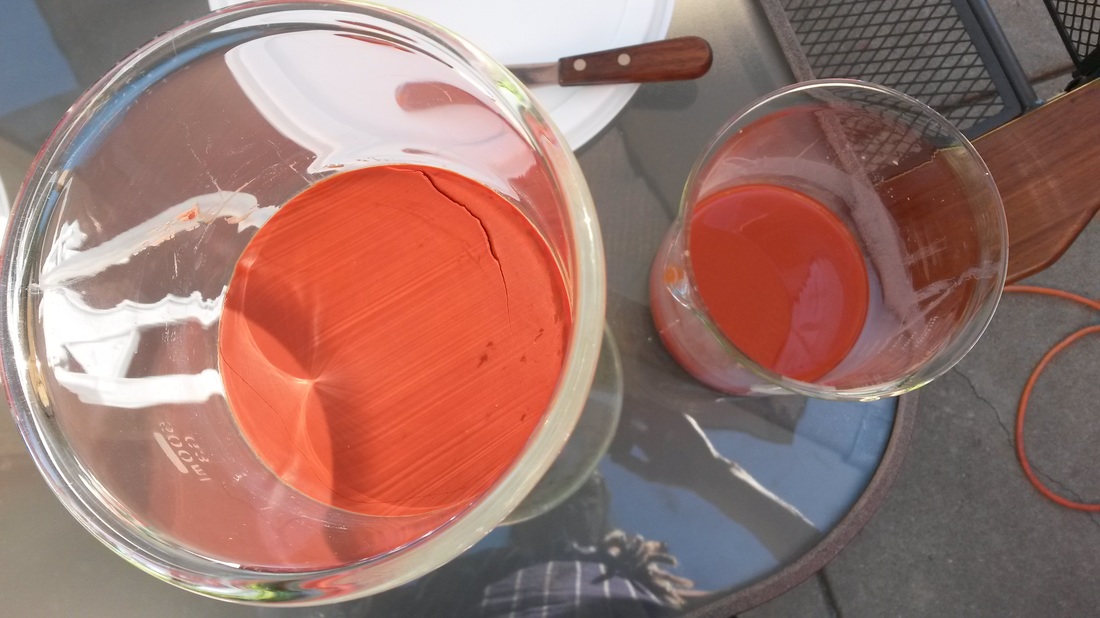

Now all I need is someone to hand it to for the purpose of breaking it in.  At the Violin Makers' Workshop in Oberlin, OH this year, we went through a process of making lake pigments that was relatively simple (if a little messy at times). I particularly liked the accuracy of the recipe we were given -- rather than the customary vague "oh, a handful of this, a pinch of that". It was with great enthusiasm I embarked on making my own pigment when I got home. I bought fancy lab equipment, and plant substances to draw colour extracts from. I set up shop on my patio. I weighed and measured, steamed and stirred. So I wasn't prepared for the strange phenomenon that followed: having followed the recipe exactly, instead of the lovely golden/orange/brown pigment we came home with from Oberlin, I ended up with somewhere between rose (looked at with kindly eyes) and brick (on a less happy day). Onwards and upwards, I suppose! By the time I've explored the full range of possibilities, I'll have the full palette, if nothing else.

For a while now, I have been dreaming about moving my workshop out of the house. The idea was to escape the inevitable onslaught of distractions ... watching the baby rabbits devour my garden and weeding what's left, for one ... and spend time around other adults doing interesting things.

When my bowmaker friend Jesse Berndt told me he had signed a lease on a studio and was looking for someone to share it with, I jumped at the chance. I collected the keys for the space today and am hoping to move in over the weekend. Once we have finished the workbench shuffle and unpacked the tools, this will mean I'll have to keep regular hours -- at least some of the time! An exciting feature of the studio building is that it features a performance space, which I am planning to make good use of ... watch this space. This has been a very busy year for me, at the school as well as in my studio, not to mention the ever-present needs of string players around the world LSF is trying to respond to. When my colleague Bill Scott offered me the chance to share a table at the American Viola Society's "Festival of the Viola" in Oberlin, OH, I was therefore quite excited ... about the idea of being able to just sit somewhere quietly for a few days. I wasn't quite prepared for hordes of excited violists, keyed-up after so many engrossing, inspiring and thought-provoking seminars, master classes and rehearsals, eagerly descending on the violas on show, sometimes en masse. Of course, there isn't a maker alive who doesn't delight in the opportunity to hear their instrument played by accomplished musicians. I had the chance to hear my viola played in Warner Hall by violist Elias Goldstein, an exciting experience -- it isn't always possible for me to arrange a concert hall for instrument try-outs. To read Laurie Niles' article about the great viola play-off, click here.

|

Archives

February 2024

|

Home |

About |

Contact |

Copyright © 2015

RSS Feed

RSS Feed